SHANGHAI 2012 – China has pushed back the intended completion date for its test thorium molten salt reactor from 2017 to 2020, the head of the project indicated here today.

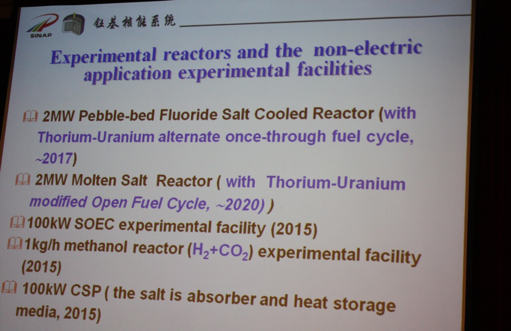

In a presentation at the Thorium Energy Conference 2012, Xu Hongjie, director of the TMSR Center at the Chinese Academy of Sciences (CAS), showed a slide stating a 2020 completion date for the 2-megawatt reactor.

That’s three years later than the 2017 set out by CAS’ Dr. Chen Kun last August in his TMSR presentation to a group of academics at the University of California Berkeley.

According to Dr Xu’s slide today, CAS has also pushed back the target date for a 2-megawatt molten salt-cooled, solid fuel thorium pebble bed reactor from the original 2015 to 2017 – although Xu seemed to say 2015 in his talk.

Whether intentional or not, Dr. Xu did not voice any date for the TMSR. The slide accompanying his talk clearly shows 2020.

During an impromptu chat afterwards, Dr. Xu would not characterize the new date as a delay. Nor did he explain in detail why CAS has pushed back the timeline.

“You need a margin,” Dr. Xu told me. “Maybe something happens.”

Sliding back. Dr. Xu’s slide shows the completion dates of 2017 and 2020, respectively, for the thorium pebble bed and thorium liquid molten salt reactors – 2 and 3 years later than previously indicated.

China approved the project in Jan. 2011. That’s practically “yesterday” in traditional nuclear development time, so the country’s original targets of 2015 and 2017 struck some people as over ambitious.

But given China’s reputation for getting things done, others found the original timescale to be plausible.

The new timescale seems to reflect the significant design challenges that have been evident over the first two days of the conference, where experts from China and around the world have described various hurdles to the thorium molten salt reactor. Among them:

- Developing materials or processes that can withstand corrosive salts, temperatures much higher than conventional nuclear, and radiation.

- Assuring that the failsafe “freeze plug” works and thus allows TMSRs to live up to the claim that they are “meltdown proof.” In a TMSR, a plug melts when the reactor overheats, allowing the liquid fuel to drain into a safe tank.

- Developing processes for the safe removal of actinides. Although TMSRs do not leave behind the longer living wastes of conventional uranium reactors, they still produce toxic elements, albeit with a shorter lifespan.

CAS, through its Shanghai Institute of Applied Physics (SINAP) division, could be well equipped to tackle these issues.

YOUTH MOVEMENT

Xu hopes to more than double his TMSR staff from 334 to 750 by 2015, hiring specialists in reactor physics, molten salts, materials, radioactivity and safety – from abroad as well as domestically.

Xu also said that the project’s youthfulness will help. Over 80 percent of its staff is under 39 years old – half are between 20 and 29 – and he is actively recruiting young scientists.

“Our team is very young, so we will be having a bright future,” he said.

In August, Dr. Chun said the test TMSR project had a $350 million budget

CAS/SINAP plans to follow its test 2-megawatt reactor with a 10-megawatt demonstrator and a 100-megawatt pilot.

Thorium molten salt reactors in principle run more efficiently than conventional reactors, produce less dangerous waste, reduce the weapons proliferation risk and eliminate the possibility of a meltdown.

China plans to use TMSRs not only to generate clean electricity, but also as a carbon-free heat source for industrial processes, the president of CAS’ Shanghai branch, Jiang Mianheng, said at the conference yesterday.